The engine nozzle increases the velocity of the exhaust gas stream by controlling its expansion and attendant pressure reduction. Optimum expansion and maximum thrust efficiency exists when gas pressure at the nozzle exit plane equals ambient pressure.

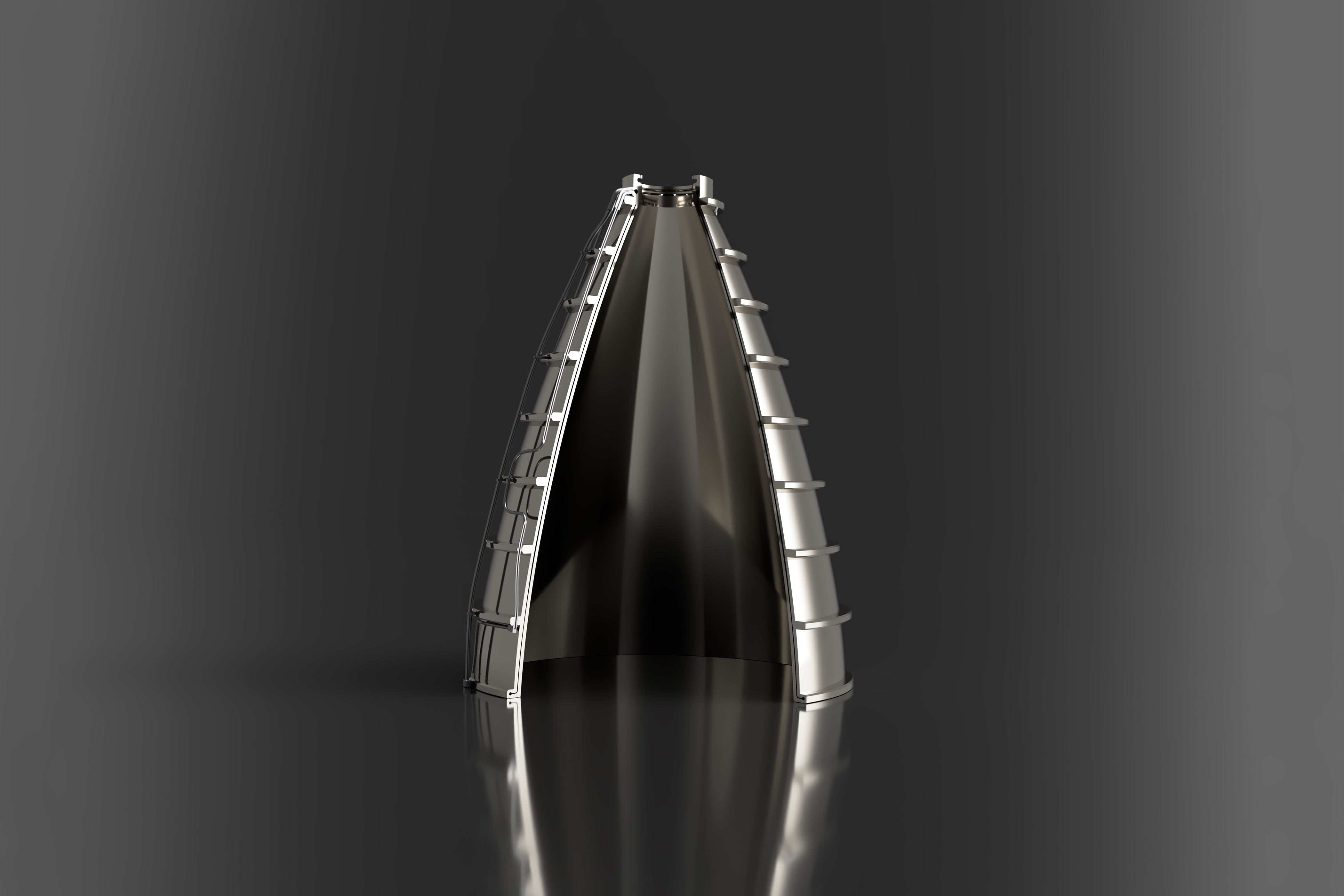

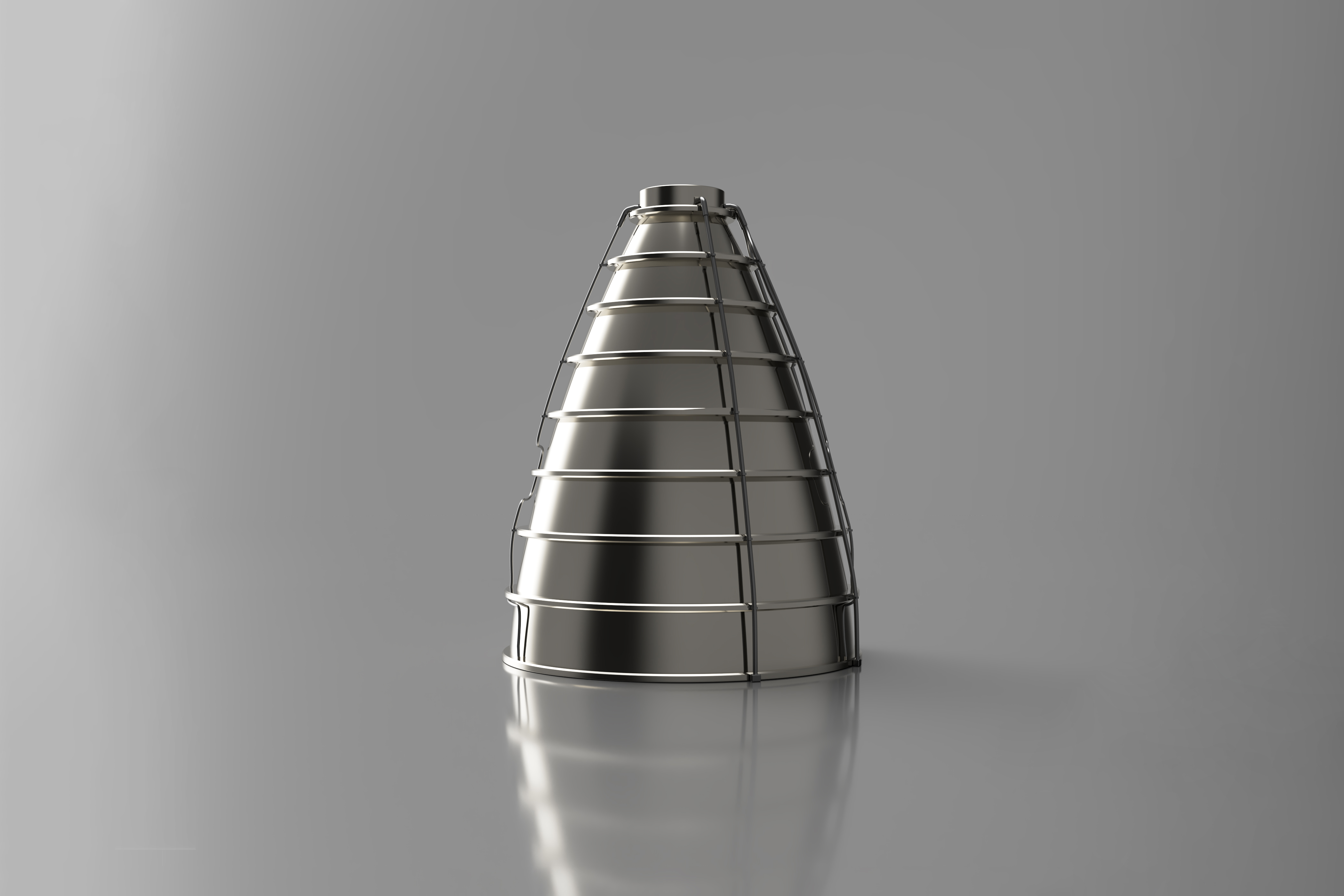

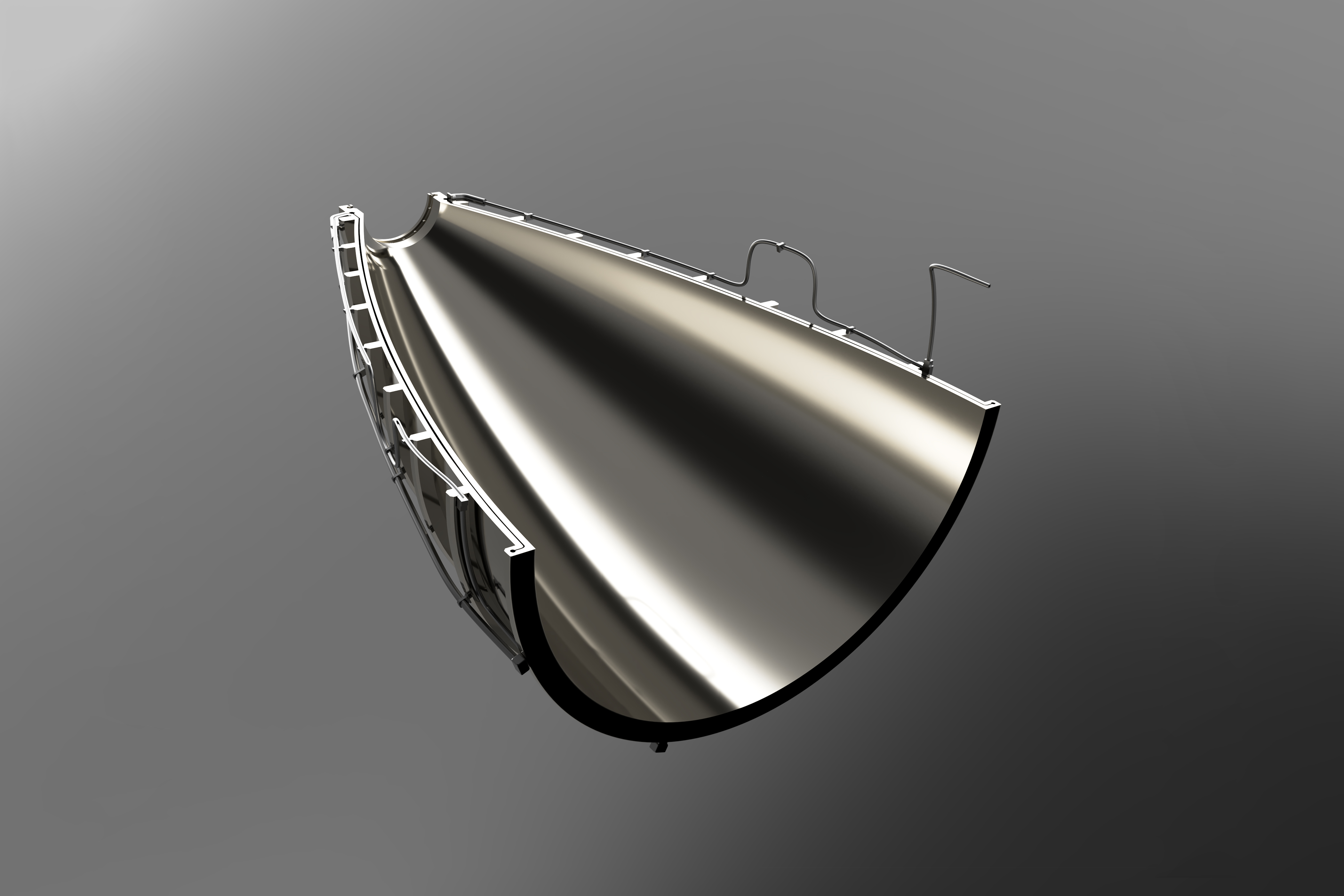

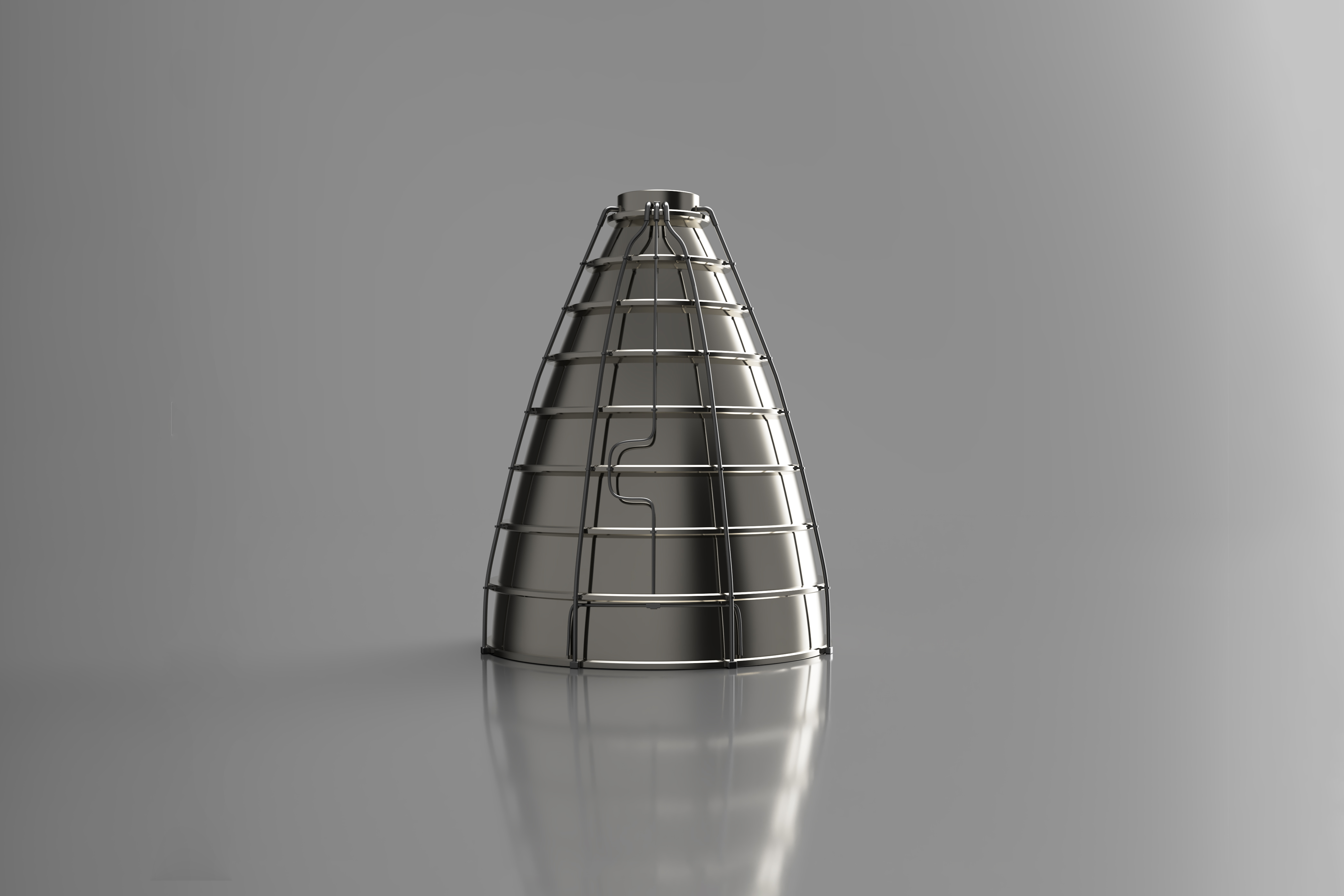

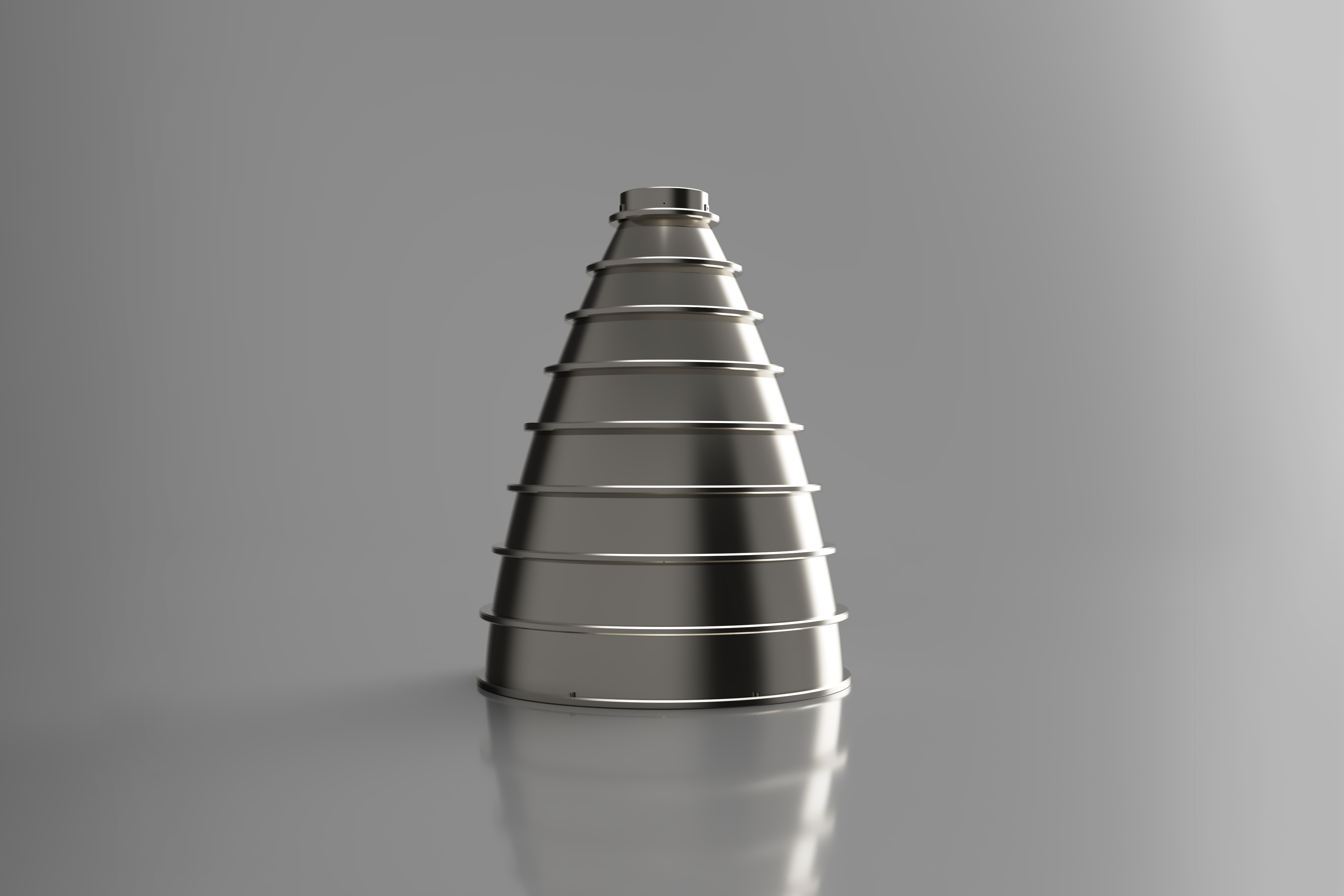

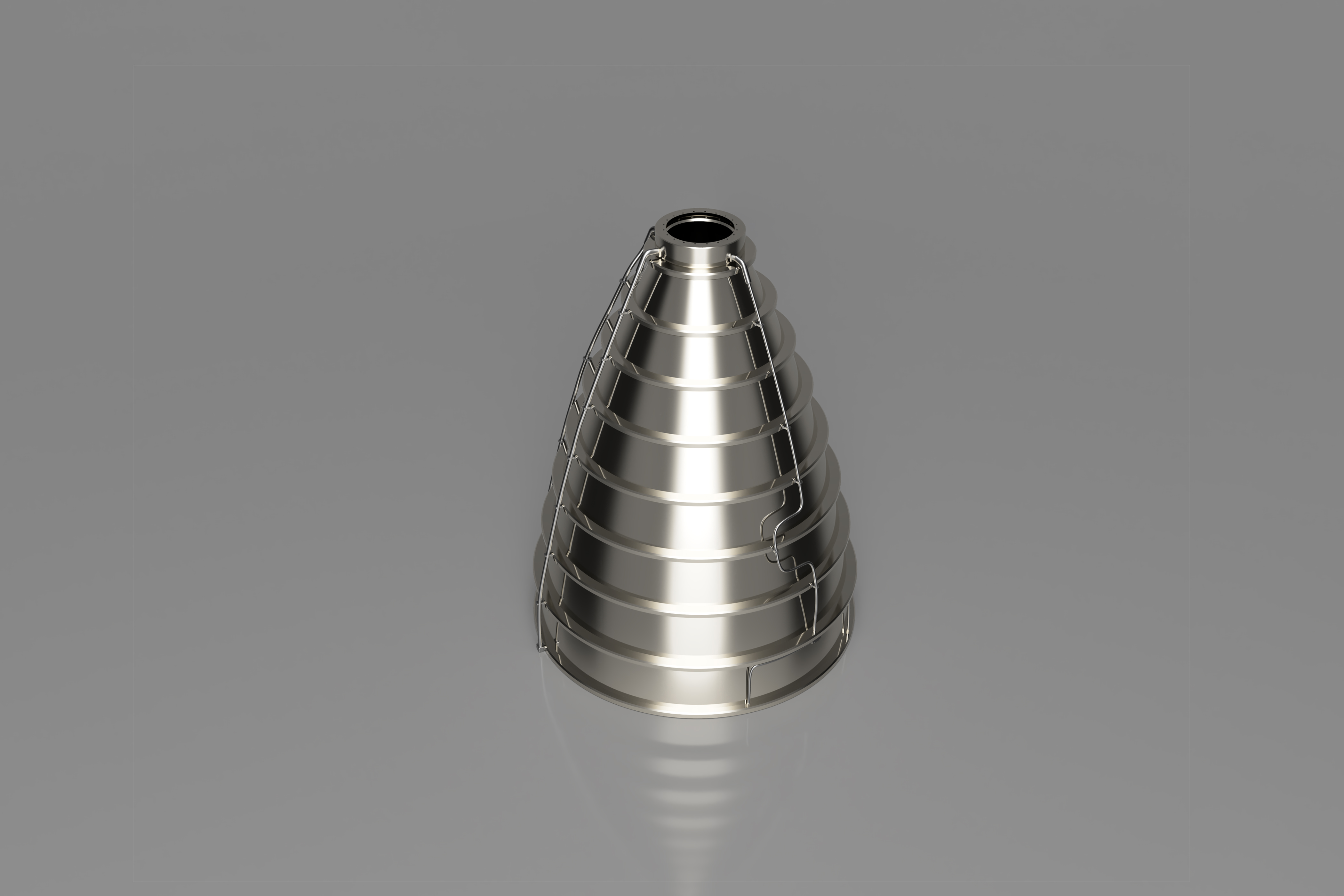

The nozzle consists of more then 1000 stainless steel tubes brazed to themselves and to a surrounding structural jacket. Nine hatbands are welded around the jacket for hoop strength.

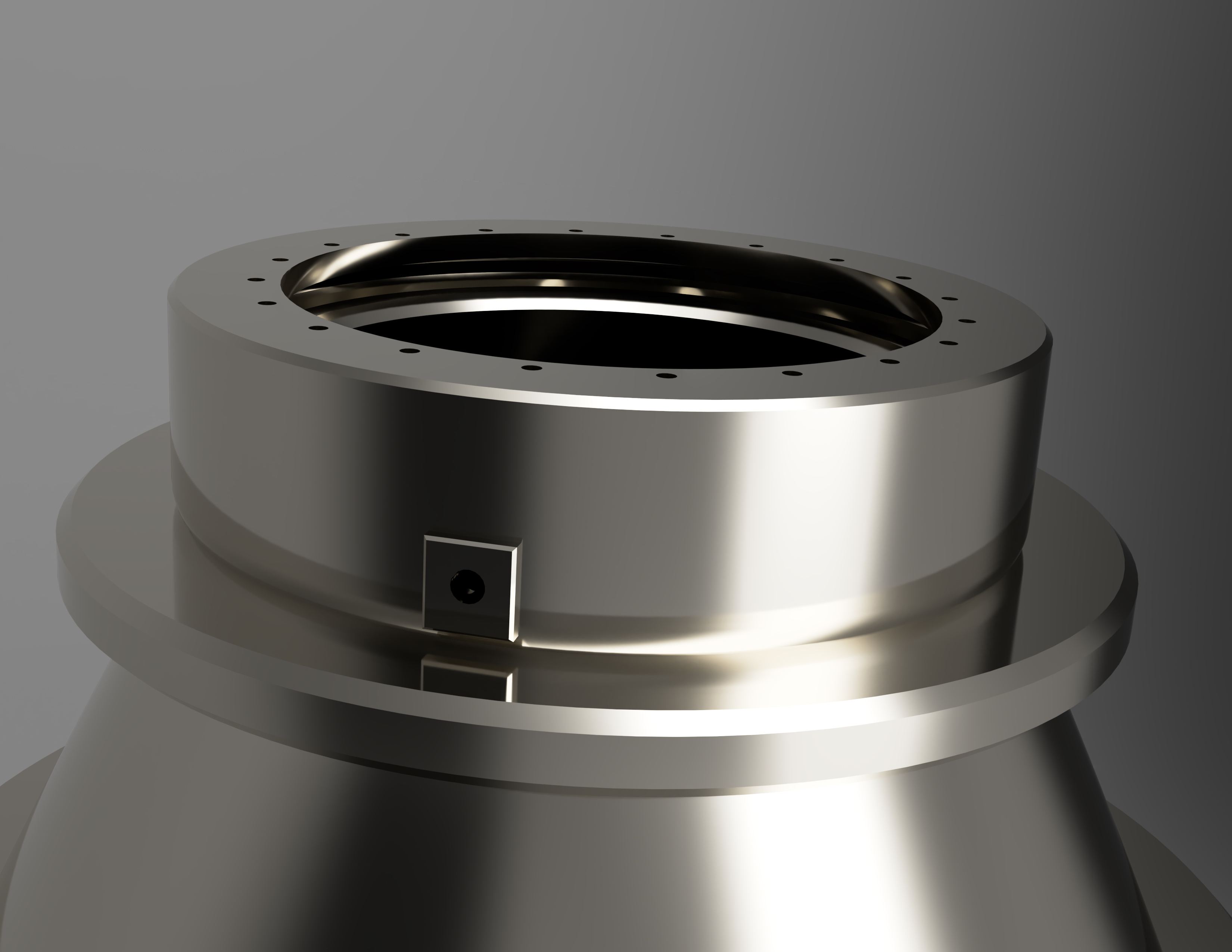

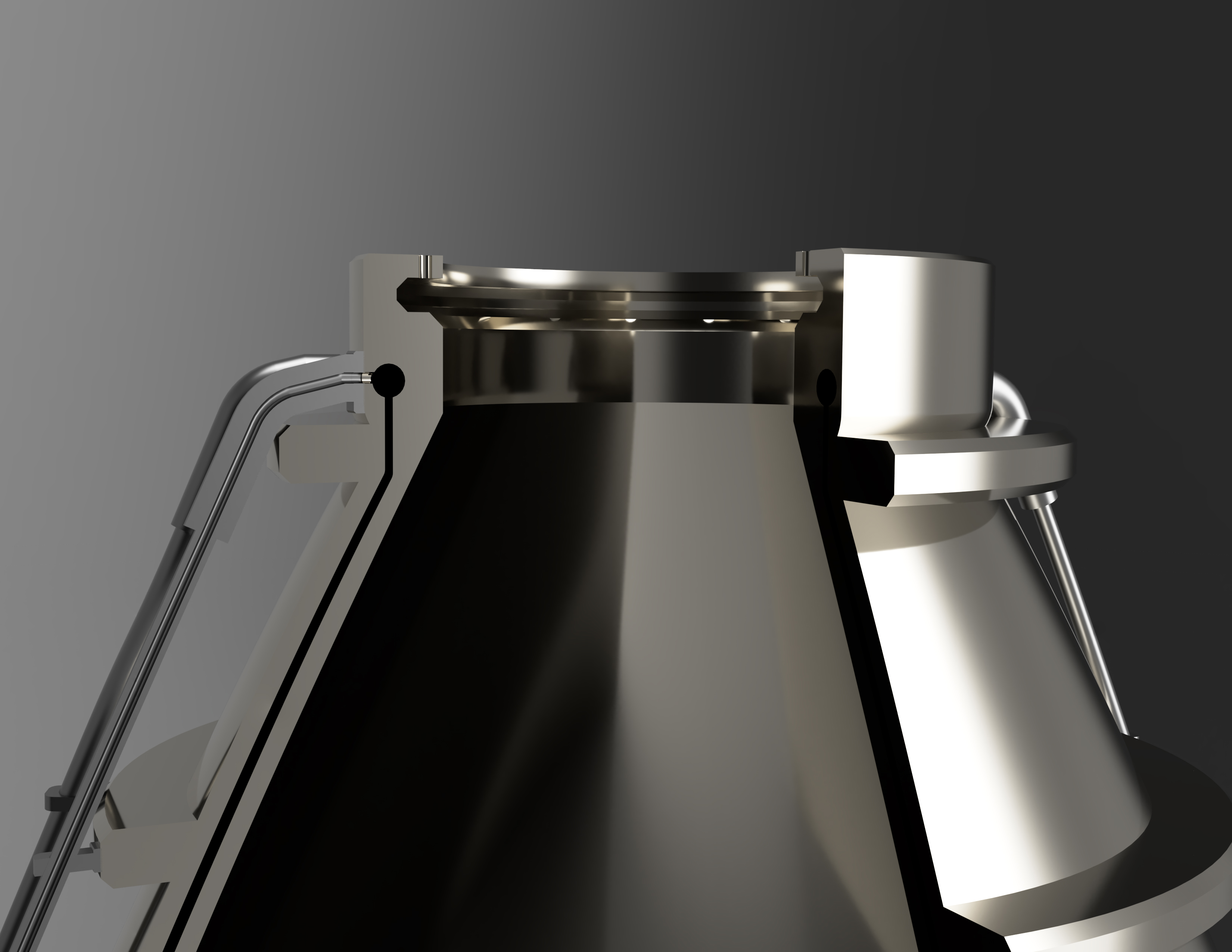

Coolant manifolds are welded to the top and bottom of the nozzle, along with three fuel transfer ducts and six drain lines.

Fuel flowing through each transfer duct splits at each ‘steerhorn’ to enter the nozzle coolant inlet manifold at six points. The fuel then makes a single up-pass through 1080 tubes to the outlet manifold.